What is Epoxy Flooring? How To Apply Epoxy Flooring

What is Epoxy Flooring

Are you looking for the most enduring and flooring for your place? For this, epoxy flooring is one most of the most practical options. Be it for commercial or industrial purposes, epoxy flooring suits such fields more efficiently in particular. On the other hand, applying normal tile, compact tiles & Kota Stone, joints will develop, but Epoxy resin can be seamless in any area. Most importantly, it is a thermosetting polymer that has distinct mechanical and chemical resistant properties.

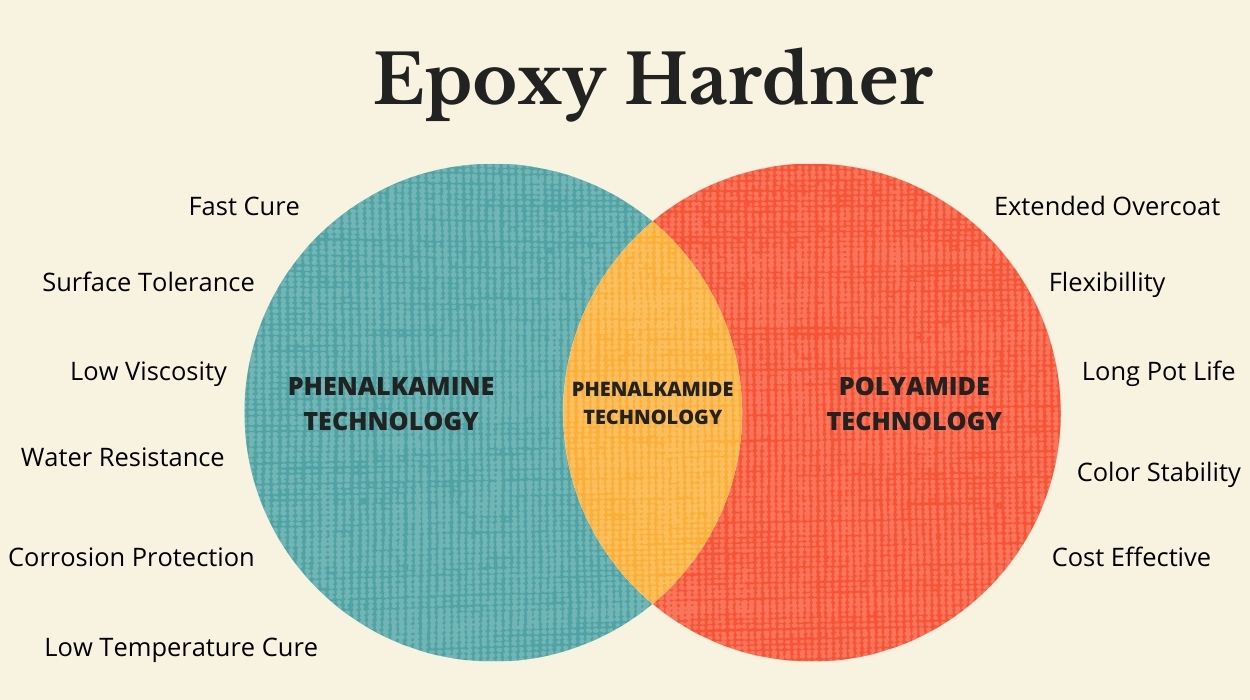

Epoxy resin gets mixed with hardener that eventually shows its chemical bonding. Such an action results in durable, stiff plastic material in particular. As a result, epoxy is a system of several layers of such thermoset polymers. Moreover, epoxy has an application on concrete floors for protection or decoration. Similarly, the resin and hardener react with the concrete surface and adhere properly. In short, the choice of having epoxy flooring benefits in managing tidy and safe conditions for workers or inventory.

Advantages of Epoxy Flooring

In comparison to other traditional options, you get more advantages by applying epoxy flooring.

Let us check them out:

- Epoxy flooring safeguards the underlying concrete from grease, stains, moisture, and cracks. Additionally, it protects from wear and tears on the existing cement floor.

- Likewise, you can get a different sort of look for your floor. These might include from the shiny surface to even dull look, for instance. Above all, such flooring remains in place for several years to come after their application.

- Moreover, the installation is easy and quick that does not demand special tools or pieces of equipment.

- Surprisingly, epoxy flooring is strong, flexible, and above all, has anti-slip coverings.

- Significantly, this epoxy has various options available to favor. So, you must prefer those colors that match your interiors, in particular. Sometimes, people specifically order epoxy flooring for decorative purposes. In addition, paints help to cover cracks and crisps.

- Most importantly, epoxy flooring has a life expectancy of over 20 years, even though it is expensive.

- Hence, you must spend your valuable amount on this flooring after much consideration. In addition, the significant part to follow is that it would benefit for a long span.

- Similarly, it is superior in performance and ideal for warehouses and industrial use.

On the other hand, epoxy is super easy to keep clean. - Significantly, its chemically resistant properties are much suitable for factories, manufacturing plants, or production plants.

- Above all, epoxy flooring does not annoy you much for maintenance.

- Epoxy resins do not permit any sort of liquid to move through. That is to say, epoxy flooring is waterproof.

Applications of Epoxy Flooring

Epoxy flooring is such a versatile option available today that it suits most industries. Interestingly, it is durable and demands less aftercare. Also, the epoxy system incorporates the addition of a variety of coatings required for different floors with different functions. On the whole, such features make it desirable for businesses to choose epoxy flooring over other conventional methods.

Therefore, check out the industries for the application of epoxy flooring:

1. Factory flooring

A rigid platform that can take high pressure daily is suitable for factories. In addition, those platforms where the traffic flow is heavy and non-stop. The wrong choice of the floor can only lead to damages and frequent wear and tears. Eventually, this would become an obstacle at the workplace.

2. Warehouse flooring

A warehouse is an area where goods are kept for their safety for a longer time, in particular. Likewise, it witnesses constant movement of people in its firm with carrying goods or driving loaded trucks. As a result, there can be a wide range of goods being stored and transferred from warehouses. In such circumstances, oil spills, grease spots, scratches, etc., can take place regularly. Also, the floor has to be tough enough to hold all the burden and last long. Therefore, epoxy flooring is one such option that can sort all your issues. Interestingly, the walkways for pedestrians, truck loading bays have markings with different colored lines of epoxy flooring. Similarly, some other areas too have such utilizations.

3. Food-grade flooring

Food-grade flooring mainly involves industries like bakeries, commercial kitchens, dairies, food manufacturing, and others. But many of these factories experience extreme temperatures. Therefore, they demand thermal shock-absorbent floors. In particular, the most preferred floors are special polyurethane resin floors. Thus, these are beneficial for food factories that offer thermal, chemical, and wet protection. Similarly, they do not encourage microbial growth, making it more suitable for food factories.

4. Car workshop flooring

Installing garage floors is not easy, but we are the experts! Epoxy Car workshop floors are added with an anti-slip safety finish. Also, they are impenetrable. Oil, grease spilled on its surface remains there and does not penetrate inside the epoxy resinous floor. Therefore, the cleaning of such floors becomes more convenient after completing any work. As a whole, it is hard-wearing, and its installation is fast. Just the way a garage owner would want!

How is Epoxy Flooring done?

Have you ever queried about the making of such an advanced floor? Well, many of you might not have. Yet, give this piece of information a read to add more layers of knowledge you might have on the subject.

Epoxy Flooring Procedures steps:

1. Surface (Concrete/ cemented) Moisture test

2. Area measurement

3. Surface Preparation

- Grinding

- Joint treatment

- Scarification (if the thickness is 3mm or more than 3mm)

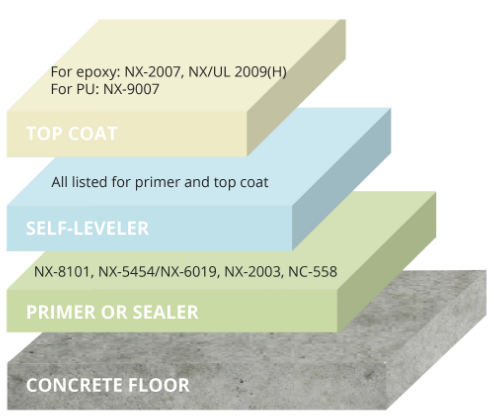

4. Primer (2nd coat will be applied if required according to the surface)

5. Screed

6. Grinding lightly & sealer coat (Self-leveling)

7. Topcoat

How To Apply Epoxy Flooring

1. Prepare the concrete surface

Let the new slab of concrete floor cure properly for 30 to 60 days before applying an epoxy coating. In order to do this, the existing concrete floor should be cleaned up, remove dust, etc.

2. Surface priming

On the clean and cured concrete floor, apply primer all over before it receives epoxy coating.

3. Mixing the components

The choice of the epoxy flooring by you becomes significant in mixing all necessary components. So, the required proportions of these components are mixed by a forced action.

Two-component system

a. Epoxy Resin

4. Application

Now, the mixer is used all over the primed cover without waiting for any moment. After this, the application of other similar coats is followed. Finally, the outer layer and the most important layer are applied.

According to FeRFA, the Resin Floor Association, there are eight resin floor arrangements. In particular, there are various proportions and formulations of epoxy, methacrylate, and polyurethane that comprise several resin examples. On the whole, you can check these organizations with their short explanation:

- Floor seal:

- Light duty

- Up to 150 micrometers in thickness

- Two or more coats are applied.

- Floor coating:

- Light duty or medium duty

- 150 µm to 300 µm in thickness

- Two or more coats are applied

- High build floor coating:

- Medium Duty

- 300 µm to 1000 µm in thickness

- two or more coats are applied.

- Generally solvent-free.

- Multi-layer flooring:

- Medium Duty or Heavy Duty

- > 2 mm in thickness

- Sandwich system of multiple layers of floor coatings or flow applied floorings

- Flow applied flooring:

- Medium Duty or Heavy Duty

- 2 mm to 3 mm in thickness

- It has a smooth surface.

- Also known as ‘self-smoothing or ‘self-leveling flooring.

- Resin screened flooring:

- Medium Duty or Heavy Duty

- > 4 mm in thickness

- Includes a surface seal coat to reduce porosity.

- Heavy-duty flowable flooring:

- Heavy Duty or Very Heavy Duty

- 4 mm to 6 mm in thickness

- It finishes with a smooth surface.

- Heavy-duty resin flooring:

- Very Heavy Duty

- > 6 mm in thickness

- The seamless surface and impervious layer

What is epoxy flooring used for?

Epoxy floor coatings are generally used for commercial and industrial flooring. It is normally applied over concrete floors to provide a high-performance and durable surface. Epoxy coatings can last many years and withstand heavy loads.

Is epoxy flooring good for homes?

Yes, Epoxy Flooring is an extremely safe coating for your home floors. It’s slip-resistant, shock resistant, and less abrasive.

How long does epoxy floor last?

It can last 2-3 years in heavy traffic places like garages, restaurants, or factory spaces

Is epoxy flooring waterproof?

Yes, epoxy flooring provides a shield against water

Epoxy flooring price in Delhi

To know about the Epoxy flooring price in Delhi you can contact reputed epoxy suppliers

Meena Gulati