What are Synthetic Resins? Applications and Uses

A synthetic resin is a chemical substance this is artificially created to mimic the traits of its naturally going on counterpart. Synthetic resins are noncrystalline or viscous liquids which might be secreted from paints.

Synthetic resins are industrially manufactured via the manner of polymerization, which includes the introduction of chain-related polymers, allowing for extra stable, homogenous resulting structures than is found in naturally going on resins.

- Saturated Polyesters

- Unsaturated Polyesters

- Alkyds

- Epoxies

- Acrylics

- Vinyls

- Polyacetals

- Polyurathanes

- Amino resins

- Phenolic resins

- Rosin modified resin

- Maleic resins

- Ketonic Resins

- Isocynate adducts

- Polyamides

- Silicones

- Cellulose acetate Butyrate

- Nitrocellulose

- Hydroxy ethyl cellulose

- Carboxy Methyl Cellulose

- Chlorinated poly propylene

Forms of Resins

1. Solid

2. Liquid

100% Liquid

Solution in Solvent

3. Emulsion

4. Dispersion

Physical Parameters of Resin

- Appearance – Solid/Liquid

- Clarity – Whether clear / turbid / hazy / free of foreign particles % Solids

- Viscosity at specific temperature

- Dilution viscosity

- Solvent Tolerance

- Specific Gravity

- Softening / melting point

- Compatibility with co-resin/other resin

- Pot life (in case of two pack coatings)

- Gel Time

Chemical Parameters

- Acid Value

- Hydroxyl value

- Amine value

- Epoxy Value

- Isocyanate content

- Formaldehyde content

- Methylol Content

Curing or Drying Parameters

- Ambient temperature Drying using driers (Metalic Soaps)

- Elevated Temperature drying using driers or crosslinker using specific ratios

Dry Film Properties

- Appearance

- Clarity of the film

- Scratch hardness

- Pencil hardness

- Impact resistance

- Flexibility

- Gloss

- Resistance to water

1. Saturated Polyesters

Saturated polyester resin is the reaction of polybasic acids and polyols and has outstanding strength and hardness in its characteristics. It is primarily used for non-stick pan,glue, PET coil, metallic baking paint like automotive paint, painting, Marker, Rolling steel. Check out uses of stearic acid.

Raw Materials

Aliphatic dibasic acids, Aromatic dibasic acids, THPA, HHPA, TMA, etc. Glycols

Functional Groups

Carboxyl, Hydroxyl, Ester

Major End Uses

Auto OEM and refinishes, coil coatings, Powder coatings

2. Unsaturated Polyesters

Copolyesters are unsaturated polyesters — that is, polyesters prepared from a saturated dicarboxylic acid or its anhydride (usually phthalic anhydride) as well as an unsaturated dicarboxylic acid or anhydride (usually maleic anhydride).

Raw Materials

Aliphatic dibasic acids, Aromatic dibasic acids like Maleic anhydride, Fumeric acid, Glycols

Functional Groups

Carboxyl, Hydroxyl, Ester, unsaturation.

Major End Uses

Wood finishes, Automobile putty

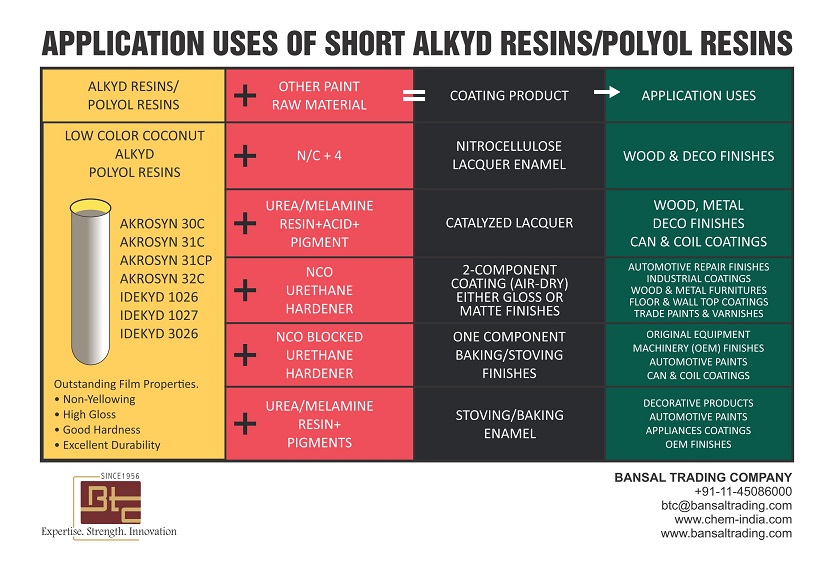

3. Alkyds

Alkyd resins are polyester thermoplastic resins made with polybasic acids or their anhydrides by heating polyhydric alcohols. These are used to produce protective coatings with strong weathering properties and due to their durability and low cost, these are important ingredients in many synthetic paints.

Raw Materials

Oils, Fatty acids, Aromatic dibasic acids, Unsaturated dibasic acids like Maleic anhydride, Fumeric acid

Functional Groups

Carboxyl, Hydroxyl, Ester, unsaturation.

Major End Uses

Architectural coatings, Industrial Coatings (Ambient Temperature drier/Elevated temperature drying)

Alkyd Resins Oil Length

An alkyd resin’s oil length is known as the amount of oil used to produce 100 grams of resin. As the resin’s oil length increases, viscosity usually decreases, the film’s hardness decreases, film durability increases, and water resistance decrease.

The word alkyd derives from alcohol and acid. Alkyds are prepared from the polyols, dibasic acids, and fatty acids condensation reaction. The portion of fatty acid is derived from vegetable matter and is, therefore, a renewable resource. The main performance characteristics of alkyds include their ability to deliver improved surface wetting (from the bio-based fatty acid portion of substrates and pigments) and lower cost (also from the fatty acid portion in particular). Glycerol, pentaerythritol, and trimethylolpropane are the most commonly used polyols, while phthalic anhydride and isophthalic acid are most widely used dibasic acids. Get some ideas on the types of pigments.

The amount of fatty acid applied to the alkyd resin polyester backbone. Oil length is specified in 100 percent solid alkyd resin as the total weight of oil. When oil length is higher than 60%, “long-oil alkyd resin,” between 40% and 60%, “medium-oil alkyd resin,” less than 40%, “short-oil alkyd resin.”

4. Epoxies

Epoxy resins are used for the manufacture of adhesives, coatings, paints, plastics, primers and sealers, floors and other items and materials used in building applications. Epoxies are plastics of thermoset formed by the reaction of two or more industrial chemical compounds.

Raw Materials

Bisphenol A & epichlorohydrin

Functional Groups

Ether, epoxy, Hydroxy

Major End Uses

Industrial maintenance coating, Chemical Resistant Paints, Electrodeposition Paints, Powder coatings.

5. Acrylics (thermoplastic)

Solvent-based acrylic coating resin is the polymer that is formed by unsaturated bonds from the cross-linking reaction between acrylic and ester monomer. Acrylic resin is made up of types of thermoplastics and thermosetting. Acrylic paint is highly heat, water and chemical resistant. Also read about the cosmetic raw materials.

Raw Materials

Soft & hard monomers

Functional Groups

Carbon Carbon bond

Major End Uses

Coating on plane substrates such as ABS, HIPS, etc. (Cabinets, Mobile phones, etc). Touch up paints(aerosol coatings), Coat on concrete.

6. Acrylic (Thermosetting)

Acrylic resin includes types of thermoplastic and thermosetting. Acrylic paint is highly heat, water and chemical resistant. In addition, it can co-polymerize to meet the performance requirements of hardness and softness with other monomers.

Used primarily in cement painting based on oil, plastic paint, marine paint, automotive baking paint, appliances / metal baking paint, automotive refinishing, wood coating, etc.

Raw Materials

Soft & hard functional monomers

Functional Groups

Hydroxyl, carboxyl, Etherified N-methylol groups, etc.

Major End Uses

Automotive Paints (top coats for metal & plastic components)

7. Polyamides (reactive)

A polyamide is a multi-unit macromolecule connected by amide bonds. Naturally and artificially, polyamides occur. Proteins, such as wool and silk, are sources of naturally occurring polyamides. Using step-growth polymerization or solid-phase synthesis, which yields materials such as nylons, aramids, and sodium poly(aspartate), polyamides can be made artificially. Because of their high durability and strength, synthetic polyamides are commonly used in textiles, automotive, carpets, kitchen utensils, and sportswear. The major consumer is the transportation manufacturing industry, accounting for 35% of polyamide (PA) consumption.

Raw Materials

Dimer fatty acid, monobasic fatty acid, triethylene tera amine, triethylene pentaamine, diethylene triamine

Functional Groups

Amide, amino

Major End Uses

Harder for epoxy coating

8. Polyamides (Non-reactive)

Polyamide resins based on dimer acid (DAB) are either reactive or non-reactive. Of epoxy resins used in surface coatings and adhesives, reactive polyamides are mainly used as curing agents. Non-reactive DAB polyamides are commonly used in hot-melt adhesives as well as in printing inks.

Raw Materials

Dimer fatty acid, Monobasic fatty acid, Ethylene diamine

Functional Groups

Amide

Major End Uses

Printing inks for polyphenic substrates

9. Pure Phenolic Resins (Resols)

The resin provided is treated using top grade chemicals. In varnishes, enamels and lacquers, this resin is widely used. In fact, at the most affordable prices, this Pure Phenolic Resin is made available to customers.

Raw Materials

Phenol formaldehyde, Alcohols, such as butanol, etc.

Functional Groups

Methylene bridge, Ether, methylol, etherified methylol

Major End Uses

Curing agent for epoxies and silicon at elevated temperatures, Sp. varnishes

10. Rosin Modified Phenolic Resins

Rosin Modified Phenolic Resin is a vacuum-treated glycerol (or penta erythrite) esterification product containing rosin, phenol (or bisphenol A) and formaldehyde polycondensate.

Raw Materials

Rosin Bis-phenol A, Para tertiary Butyl phenol, Paraformaldehyde Penta, glycerine

Functional Groups

Methylene bridge, ether, methylol, etherified methylol

Major End Uses

Printing inks, Vehicles, Hammer tone binders

11. Rosin Modified Maleic Resins

Maleic resin is produced by esterification with the polyhydric alcohol from gum rosin and maleic anhydride. UMaleic resins are used to improve shine, hardness, drying rate, abrasion resistance and yellow resistance primarily for surface coatings and primers. In Toluene, Xylene, White Spirits, completely Soluble.

Raw Materials

Rosin, Maleic anhydride, Fumeric acid, penta, glycerine, etc.

Functional groups

Ester, carboxyl, hydroxyl

Major End Uses

Picture varnish, Flexo inks, hammer tone binder, nitro cellulose based paints.

12. Isocyanate Adducts

In many industrial fields, polymers prepared by polyisocyanate reaction, hereinafter referred to as isocyanate adducts, are used. For example, polyurethanes, poly isocyanurates and polyureas are adducts of isocyanate.

Also read about the polyurethane resin uses

Raw Materials

TDI, HDI, IPDI, TMP

Functional Groups

Urethane, isocyanate

Major End Uses

Crosslinker for alkyd, epoxy and acrylic polyol

13. Amino Resin

Amino resins are polymers that are thermosetting created by combining an aldehyde with an amino (NH2) group compound. Urea–formaldehyde (U / F) accounts for more than 80% of amino resins; most of the remainder are accounted for by melamine–formaldehyde. Certain aldehydes and other amino compounds are used for a very low extent.

Raw Materials

Urea, Melamine, Paraformaldehyde, Butanol

Functional groups

Ether, Methylol, etherfied methylol, imino

Major End Uses

Crosslinker for alkyd, epoxy and acrylic polyol.

14. Ketonic Resins

Ketone-aldehyde resins are condensation products of cyclohexanone and an aldehyde such as formaldehyde or isobutyraldehyde, also known as cyclohexanone or ketonic resins. … When mixed with these resins, gloss, hardness, adhesion, and heat and light resistance are often improved.

Raw Materials

Cyclohexanone, isophorone, formaldehyde

Functional Groups

Ether, Methylene, hydroxyl

Major End Uses

Picture varnishes & Flexo inks

15. Silicones

Silicone resins are a form of silicone material formed by branched, cage-like oligosiloxane with a general RnSiXmOy formula, where R is a non-reactive substituent, usually Methyl (Me) or Phenyl (Ph), and X is a functional group of Hydrogen (H), Hydroxyl (OH), Chlorine (Cl) or Alkoxy (OR).

Raw Materials

Silane diols, silane triols

Functional Groups

Silicon oxygen bond, ether, hydroxyl

Major End Uses

Heat resistant coatings

16. Vinyls

Vinyl ester resin, or often simply vinyl ester, is a resin formed with acrylic or methacrylic acids by esterification of an epoxy resin.

Raw Materials

Vinyl chloride, vinyl acetate, maleic anhydride

Functional Groups

carbon carbon bond, carboxyl, hydroxyl

Major End Uses

Modifying resin

17. Polyacetal Resins

Polyacetal resins, also classified as acetal or polyoxymethylene (POM) resins, are essential engineering resins with outstanding wear resistance and extraordinary chemical, thermal, electrical and mechanical properties.

Raw Materials

Polyvinyl alcohol, formaldehyde, butyraldehyde

Functional Groups

carbon carbon bond, ether, hydroxyl

Major End Uses

Etch primer, flex inks

At Bansal Trading Company the chemical suppliers in India, everything we do is based on experience, power and creativity. They are also one of the pigment manufacturers in India. The best chemical supplier and 100% trust builded products are been served for years. You can contact us for more details & follow ups!

BTC_WEB_ADMIN